Sebiav rov or luv iav fibers, prime fiberglass or precio fibra de carbonotau ntxiv rau cov thermoplastic matrix, lub hom phiaj tseem ceeb yog txhawm rau txhim kho cov khoom siv hluav taws xob thiab cov qauv ntawm cov polymer.Muaj ntau qhov sib txawv ntawm ob txoj hauv kev tseem ceeb ntawm kev txhawb nqa cov thermoplastics rau kev txhaj tshuaj molding, los ntawm yuav ua li cas lawv ua ke nrog cov polymer matrix, mus rau theem ntawm kev ua tau zoo lawv tuaj yeem muab tau, thiab ib daim ntawv fiber ntau yuav yog qhov zoo dua, tab sis rau tus shaper, qhov sib txawv tseem ceeb ntawm luv thiab ntev fibers yog cov degree uas lawv tau ua tiav.

Ua ntev fiber reinforced thermoplastics

Lub hom phiaj tseem ceeb ntawm kev ua cov thermoplastic ntev fiber ntau yog kom muaj fiber ntau ntev, uas yog qhov tseem ceeb rau kev ua kom lub zog thiab tawv.Fiber breakage tuaj yeem ua rau muaj kev cuam tshuam tsis zoo rau cov khoom ntawm cov khoom siv polymer thiab tej zaum yuav tsis pom qhov txiaj ntsig ntawm kev siv iav fiber ntau threads.Kev tuav tsis raug thiab kev siv cov cuab yeej tsis raug thiab cov qauv tsim, lossis kev siv cov khoom siv ua haujlwm tsis zoo lossis kev teeb tsa, tuaj yeem ua rau fiber ntau tawg.

Tsis zoo li chopped fiber reinforced plastics, ntev fiber reinforced cov ntaub ntawv feem ntau yog ua los ntawm pultrusion.Cov txheej txheem yuav ncabiavs rovimpregnated nrog thermoplastic resin los ntawm ib qho tshwj xeeb impregnation tuag (kom cov resin tuaj yeem qhwv ib ncig thiab khi cov fibers), thiab tom qab ntawd txiav cov extruded strands rau hauv pellets, cov fibers hauv cov pellets feem ntau yog 12 hli Qhov ntev, tag nrho-ntev nta unidirectional fiber reinforcement. , thiab qhov ntev no yog qhov tseem ceeb rau kev ua kom cov polymer ua tau zoo hloov kev ntxhov siab rau cov fibers muaj zog.

Thaum cov pellets no siv rau kev txhaj tshuaj molding, cov fibers ntev tau ua raws thiab nruj nreem qhov txhab los ua ib lub cev pob txha uas muab lub zog thiab tawv.Piv rau cov ntaub ntawv luv-fiber puv, cov khoom sib txuas ntxiv nrog cov fibers ntev, txawm tiasfiberglass fiber ntaulos yog carbon fibers, muab ntau zog-rau-qhov hnyav piv, cuam tshuam toughness, ntev cyclic qaug zog lub neej, thiab dav tshav kub kuj thiab zoo dua dimension stability.

Cov khoom siv ruaj khov no muab cov qauv kev ua tau zoo piv rau cov hlau, tseem yog sib zog dua hlau, thiab muaj peev xwm ua kom zoo dua ntawm kev ua haujlwm zoo ntawm kev txhaj tshuaj molding.1k carbon fiber ntaubtshwj xeeb tshaj yog muaj txiaj ntsig zoo li kev hloov hlau vim tias lawv yog 70% sib zog dua hlau thiab sib zog dua hlau.Aluminium yog 40% sib dua, yog li cov khoom siv fiber ntau ntev tuaj yeem siv los tsim cov khoom xav tau hauv tsheb, cov khoom ua si, aerospace, cov khoom siv thiab cov khoom lag luam.Lub hauv paus resins muaj xws li polyamide (PA lossis nylon), polypropylene (PP), rigid thermoplastic polyurethane (ETPU), thiab kub kub resins xws li polyetheretherketone (PEEK), polyphthalamide (PPA), thiab polyamide.Ether imide (PEI) thiab lwm yam. Thaum cov thermoplastic tuaj yeem txhawb nqa nrog fibers, tsuas yog qee qhov muab kev ua haujlwm siab dua vim tias lawv muaj zog dua.Ntau qhov tseeb, semi-crystalline resins tau zoo dua los ntawm fibers dua li amorphous resins, uas txhais tau hais tias lawv cov tawv nqaij thiab lub zog tau nce ntau dua.

Ua cov ntsiab lus ntawm Long Fiber Reinforced Materials

Piv nrog rau cov tsis hloov pauv lossis cov hmoov nplej uas muaj cov hmoov nplej, molding ntev fiber ntau reinforced composites muaj qee yam yuav tsum tau ua ntawm pwm, rooj vag, cov khoom siv molding, thiab tsim ib feem.Cov txheej txheem siv los ua cov ntaub ntawv no kuj txawv ntawm cov luv fiber reinforced polymers.

Raws li tau hais ua ntej, kev tuav cov fiber ntau ntev yog tus yuam sij rau kev vam meej.Cov yam tseem ceeb uas tuaj yeem ua rau lub sijhawm luv luv ntawm cov fiber ntau suav nrog kev kub siab thiab shear los ntawm kev txhaj tshuaj, raws li tuaj yeem ua rau lub kaum ntse ntse hauv cov pwm thiab cov kab khiav.Txhawm rau kom muaj fiber ntau ntev, muaj 3 lub ntsiab lus tseem ceeb ua kom paub txog:

1. Pwm khoom thiab tsim

Txawm hais tias ntev fibers hnav tsawg dua ntawm cov pwm dua li cov fibers luv vim tias muaj tsawg dua koob zoo li fiber ntau uas cuam tshuam rau pwm, tib hom pwm hlau yog tsim rau ob qho tib si ntev-fiber thiab luv-fiber reinforced polymers, feem ntau yog thawj. yog P20 pwm hlau, uas tuaj yeem tiv taus ntau tshaj 100,000 txhaj tshuaj tsis tu ncua.Yog tias yuav tsum tau ua kom muaj zog dua (siab dua 100,000 lub voj voog txhaj tshuaj), H13 chrome molybdenum steel lossis A9 cua hardened hlau yog qhov kev xaiv zoo dua.Feem ntau, cov pwm tawv tawv yog qhov kev xaiv zoo tshaj plaws rau kev ua cov fiber ntau siv cov thermoplastics.Rau cov pwm hnav, lawv tuaj yeem kho dua tshiab siv tshuab electroplating.Txhuas pwm tuaj yeem siv tau yog tias cov qauv yuav tsum tau ua kom muaj txiaj ntsig zoo rau kev tsim qauv.

2. Cov khoom siv tsim

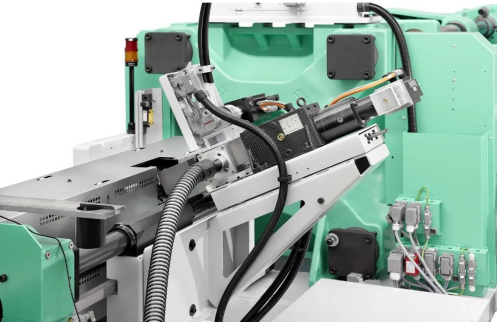

Ntev-fiber reinforced thermoplastics tuaj yeem ua tiav siv cov txheej txheem txhaj tshuaj molding khoom nrog tsuas yog qee qhov kev hloov kho tsis tu ncua los khaws cov fiber ntau ntev thiab ua kom muaj viscosities siab dua.Lub siab tsis tshua muaj siab lossis lub hom phiaj dav dav nrog lub nplhaib tsis rov qab uas tso cai rau kev khiav tawm ntawm sab saum toj yog pom zoo.Lub hom phiaj dav dav siv tau, tab sis cov nylon nozzles yuav tsum raug zam vim tias lawv cov duab moos (tsim los tiv thaiv drooling) txwv tsis pub ntws, tsim shear, thiab ua rau fiber ntau abrasion.Lwm cov lus qhia kom txo qis shear yog kom tsis txhob inverted cone nozzle designs.Feem ntau, qhov loj nozzle qhov (tsawg kawg 5.6 hli) pab txhawb kev hla ntawm cov khoom siv fiber ntau ntxiv.

Txoj cai zoo ntawm tus ntiv tes xoo rau txhua lub tshuab txhaj tshuaj tsuas yog txhaj 60-70% ntawm qhov ntim.Kev txhaj tshuaj ntau dhau ua rau lub sijhawm rov pib dua, thaum txhaj tshuaj me me txhais tau hais tias cov khoom nyob hauv lub thoob kom ntev dua, uas ua rau muaj kev puas tsuaj.

3. Cov txheej txheem ua haujlwm

Raws li kev ua haujlwm muaj kev txhawj xeeb, nws yog ib qho tseem ceeb los daws ob qhov teeb meem: warpage thiab creep.Nyob rau hauv dav dav, ntev fiber reinforced thermoplastic qhov chaw muaj kev warpage tsawg dualuv strand fiberglassqhov chaw vim hais tias cov winding ntawm cov filament txo qhov sib txawv shrinkage, tab sis txhaj molded ntev fiber ntau tseem deform, ib tug yog vim li cas yog hais tias cov fibers ntws raws lub Orientation alignment, thaum txhim kho ib feem lub zog, tuaj yeem ua rau anisotropy.Txhawm rau tiv thaiv kev tsis sib haum xeeb, lwm qhov chaw ntawm lub qhov rooj lossis cov qauv tsim tuaj yeem siv los ua kom tsis txhob muaj fiber ntau nyob rau hauv cov cheeb tsam uas tsis tas yuav muaj lub zog siab los tiv thaiv cov khoom siv.

Khaws qhov zoo ntawm cov fibers ntev

Kev ua tiav zoo ntawm cov khoom siv fiber ntau ntev ntev yuav tsum muaj qee qhov kev hloov kho ntawm cov txheej txheem tsim thiab kev ua haujlwm tsis muaj feem xyuam rau cov khoom siv tsis muaj zog thiab luv fiber ntau.Txhawm rau kom tau txais txiaj ntsig zoo tshaj plaws ntawm cov khoom siv fiber ntau ntev (uas raug nqi ntau dua li cov khoom siv tsis tau los yogfiberglass tws strands reinforcementvim lawv cov kev ua tau zoo), cov kev coj ua zoo tshaj plaws yuav tsum tau ua raws li cov txheej txheem.Yog tias cov fibers ntev tau tawg lossis tsis zoo vim kev tuav tsis raug, tuag tsim lossis teeb tsa cov cuab yeej, lawv lub zog siab thiab cov txiaj ntsig siab toughness yuav ploj mus lossis txawm ploj.

#iav rov#luv iav fibers#1k carbon fiber ntaub#luv strand fiberglass#fiberglass tws strands reinforcement

Post lub sij hawm: Oct-21-2022